Body

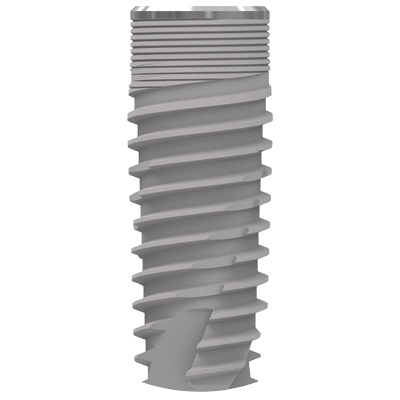

- Reduced angle active coils: promote stability during insertion and increase the BIC.

- Double loop: insertion with reduced surgical time.

- Active apex with apical windows: self-crushing, facilitates osteotomy during insertion.

- Morphology designed to achieve high primary stability.

Connection

- Adjustment by friction in internal cone of 45º. Connection depth 2mm.

- Internal hexagonal connection.

Cortical area

- 0.4 mm machined ring: avoids exposure of treated surface to irregular crest

- Micro-thread design: maintains crestal bone.

- Micro-thread extension: better load distribution.

- Macro-design: optimal cortical compression.

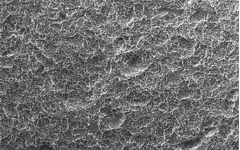

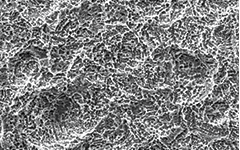

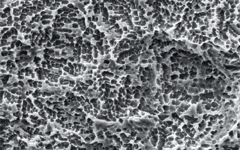

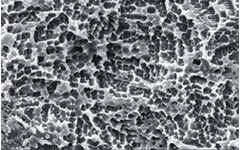

DentPross® Surface

DentPross® surface

The Dentpross® surface is achieved by the sandblasting procedure followed by a double acid etching on the implant surface and finally an argon plasma decontamination process.

This procedure achieves a microtopography on the implant surface similar to the bone structure, giving the implant surface a homogeneous macro-micro porosity.

This homogeneity of the surface, with optimum average values, favours the wettability of the surface and, therefore, the retention of the clot, enhancing the adhesion of the osteoblastic cells that initiate ostogenesis.

Dentpross® features

- Pure surface of TIO2.

- Porous Macro-Micro surface.

- Homogeneous porosity.

- Optimum average values.

- Osteoconductive surface.

- Great biological stability.

- Superficial structure similar to bone.

- High surface wettability.

- Contaminant free surface topography.

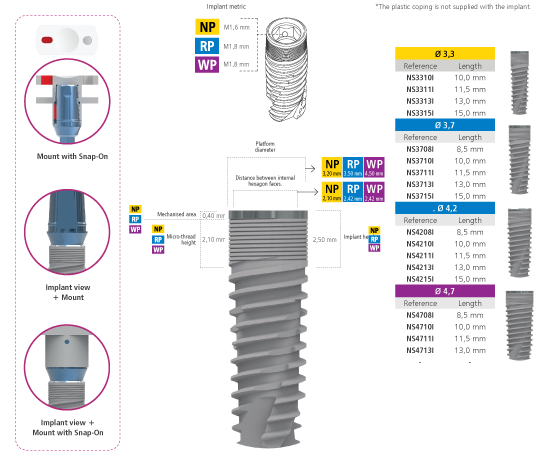

Dentpross® Mount

Dentpross® Mount with Snap-On

This Mount is designed as a multifunctional grade 5 titanium abutment with a sculptable abutment morphology that is easy to prepare for cementing.

The plastic coping can be used as an impression for closed tray. Due to its characteristics, Mount DentPross® is an abutment with three functions: Mount, impression abutment for Snap-On for closed tray technique and sculptable abutment.

The plastic coping for Snap-On* has an internal straight surface which is guided through the upper grooves and aligned with the plane of the abutment. After sliding under pressure, it is snapped into the lower abutment groove ensuring secure retention for impression taking and subsequent abutment replacement.

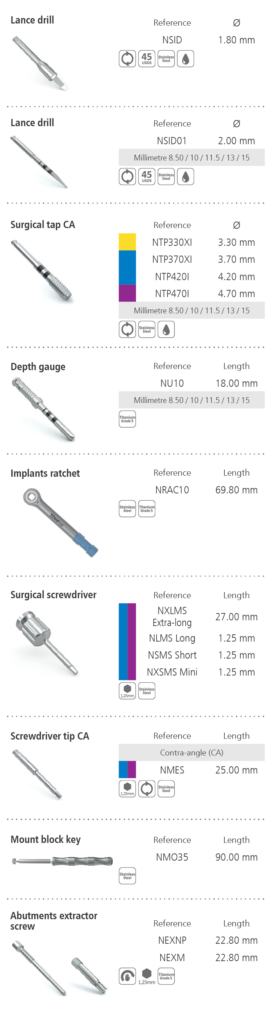

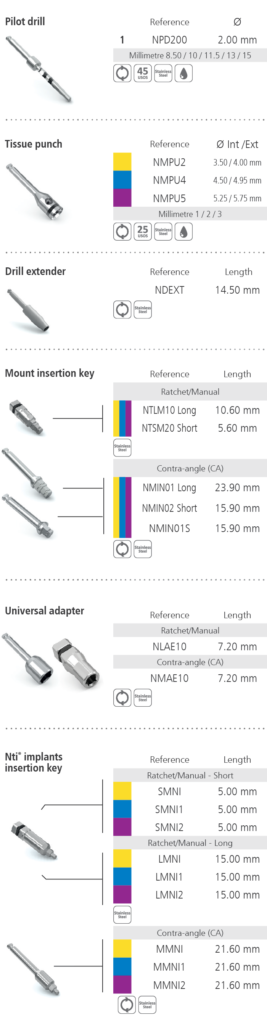

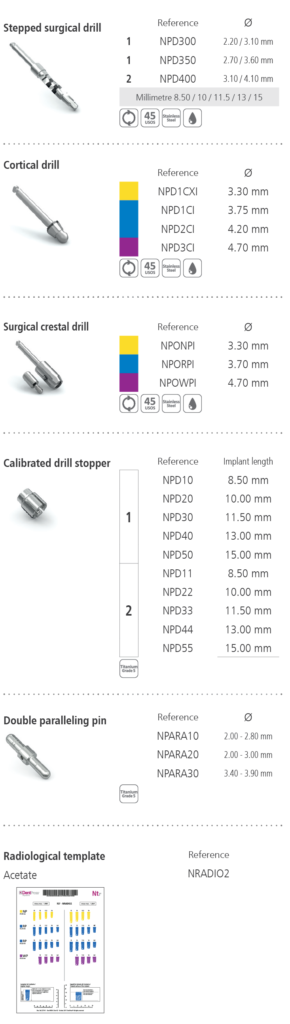

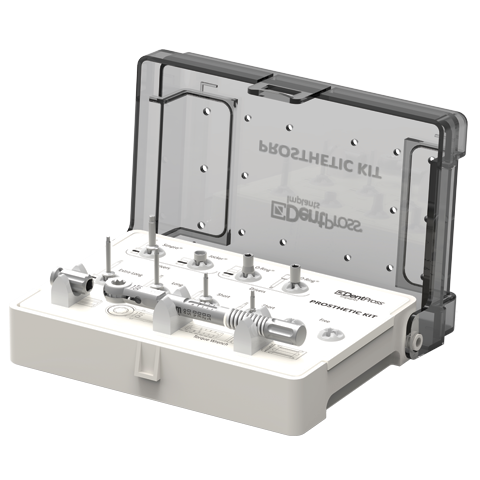

Surgical box and prosthetic kit

Surgical box internal connection Ntx®/Nti®

Prosthetic box external connection Ntx®/Nti®

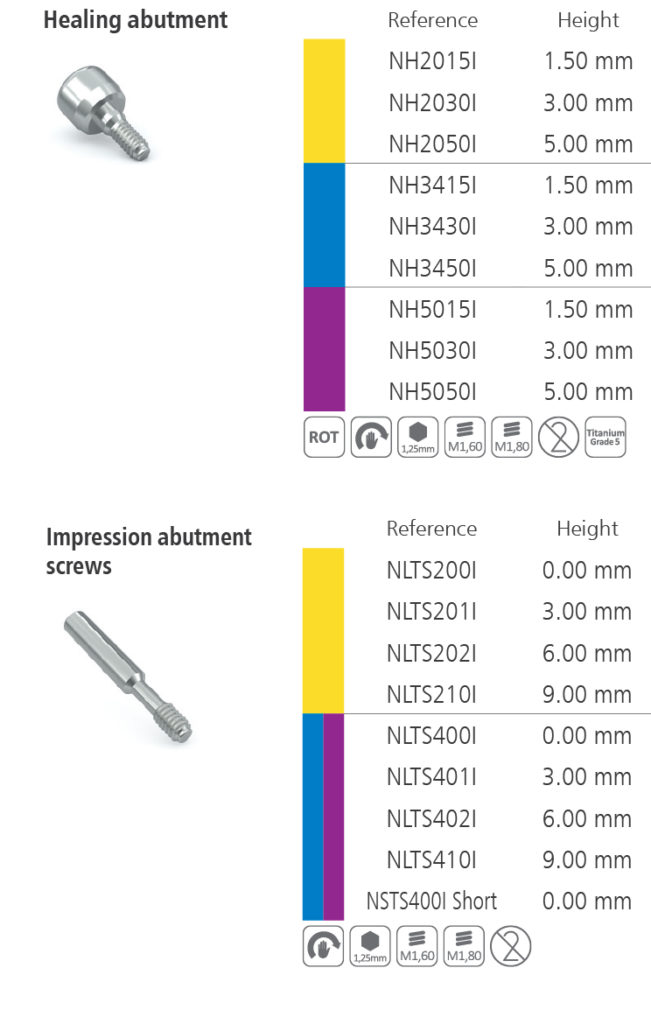

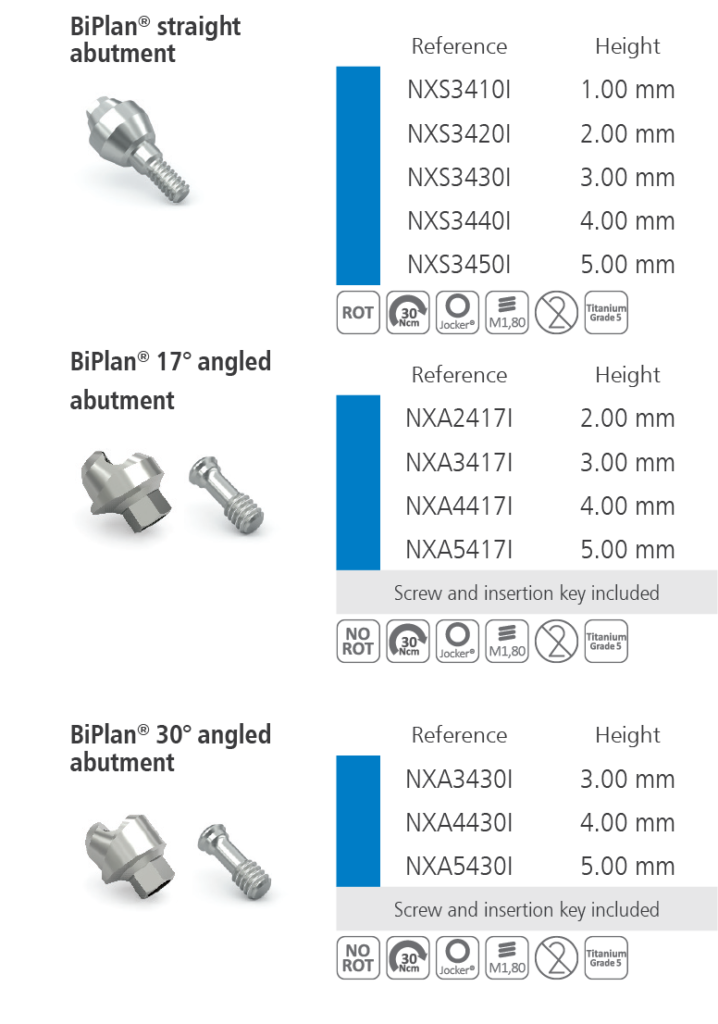

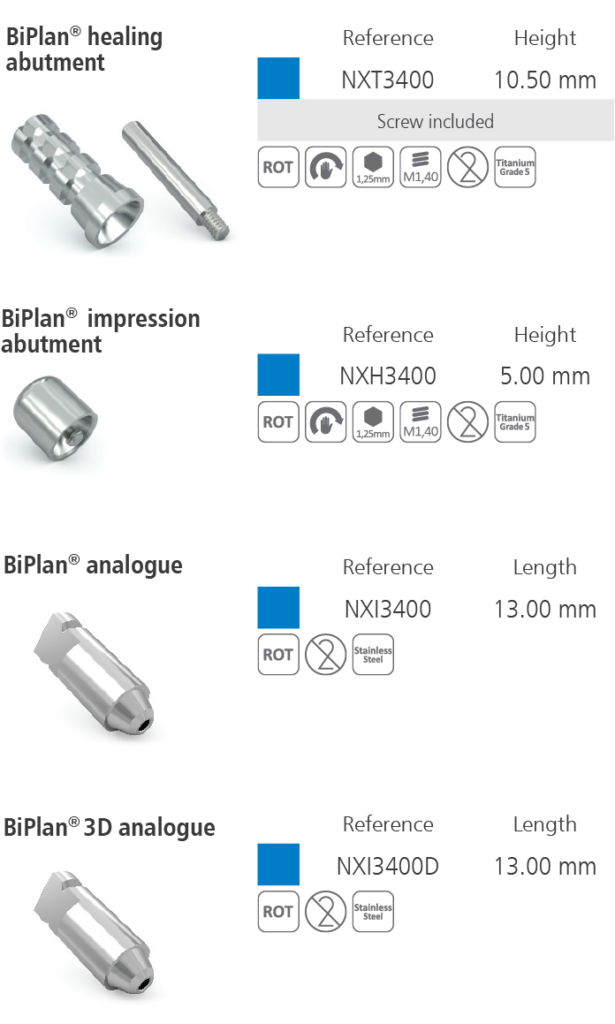

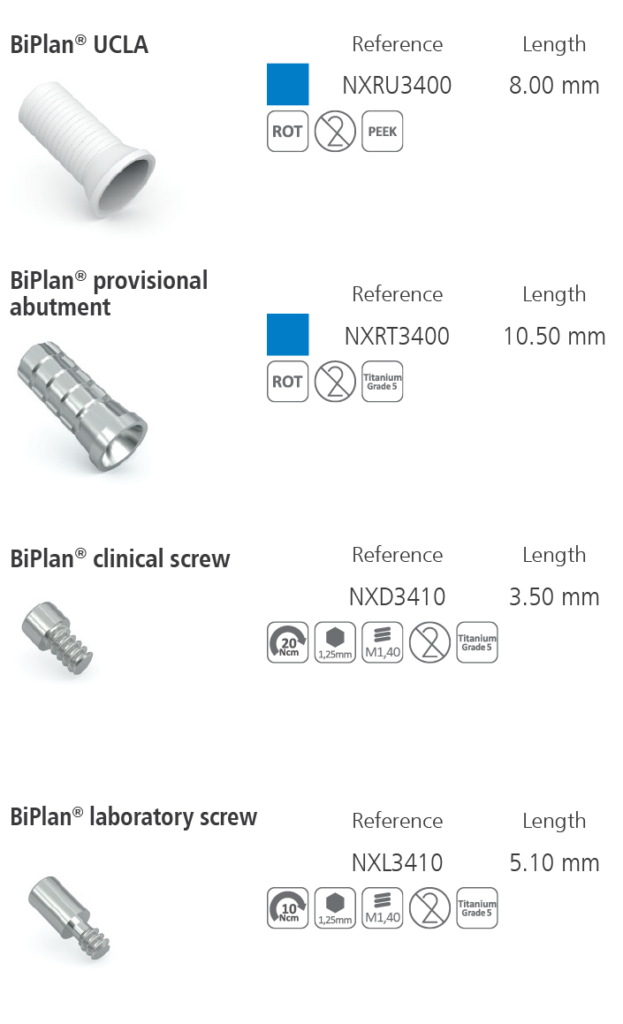

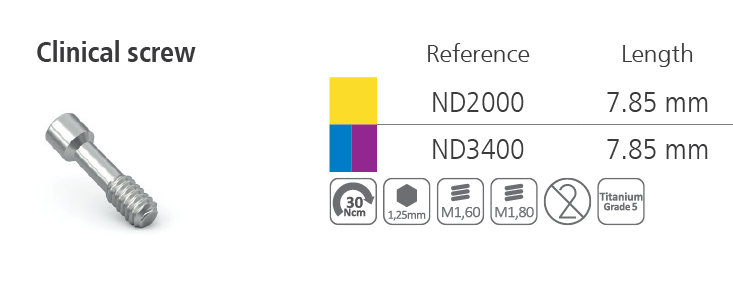

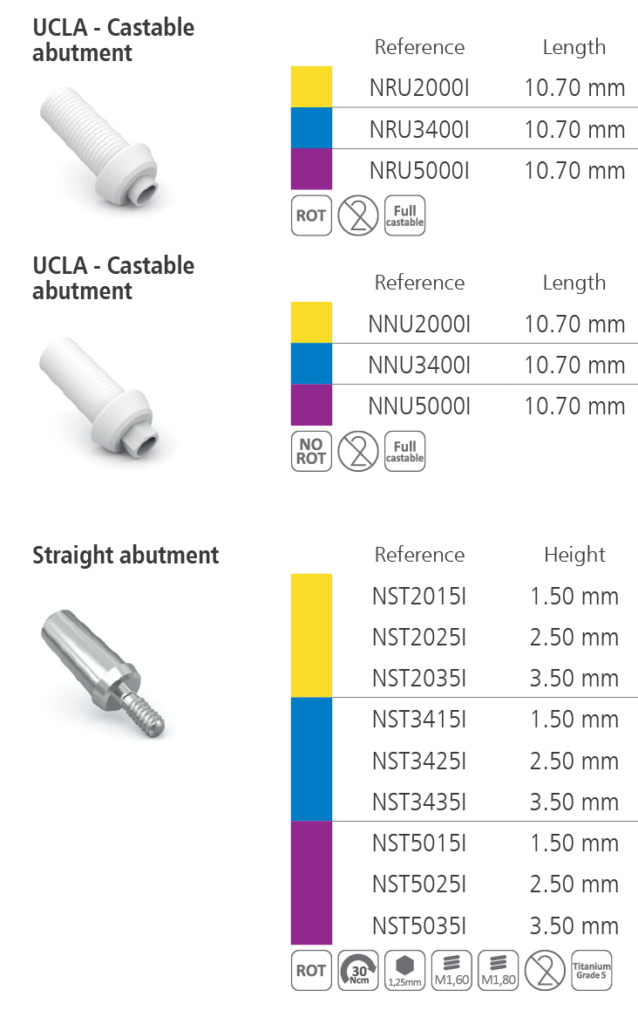

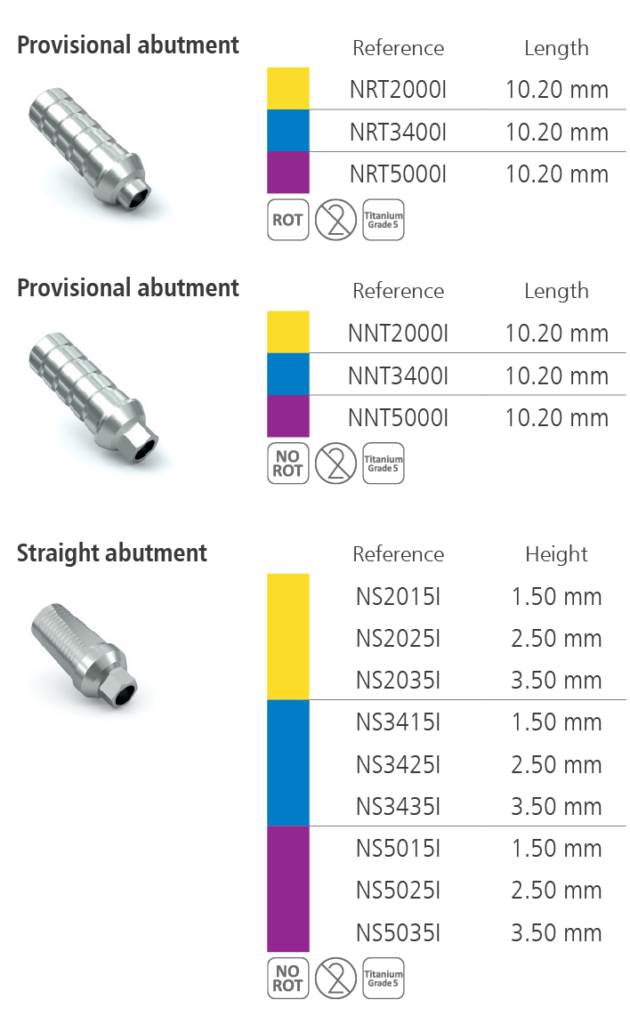

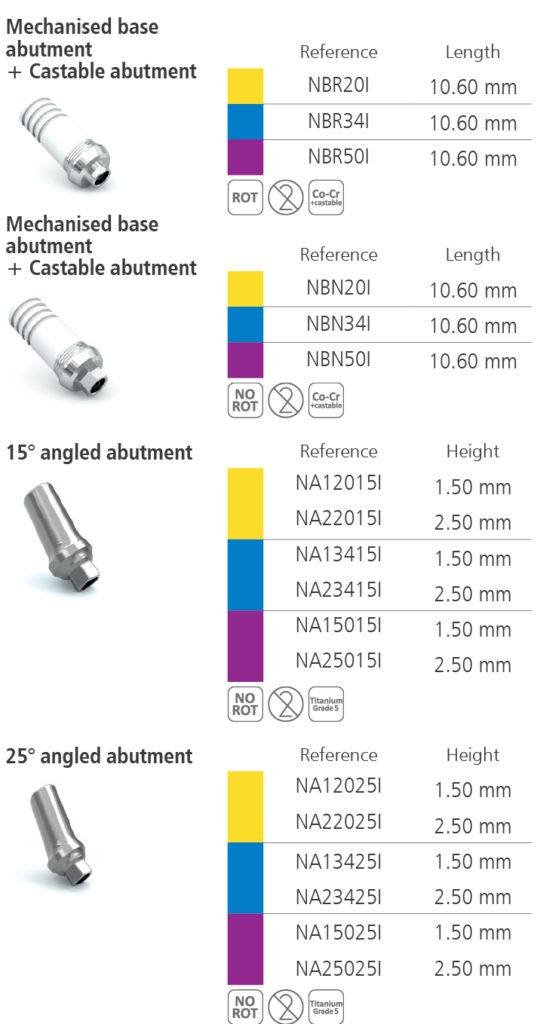

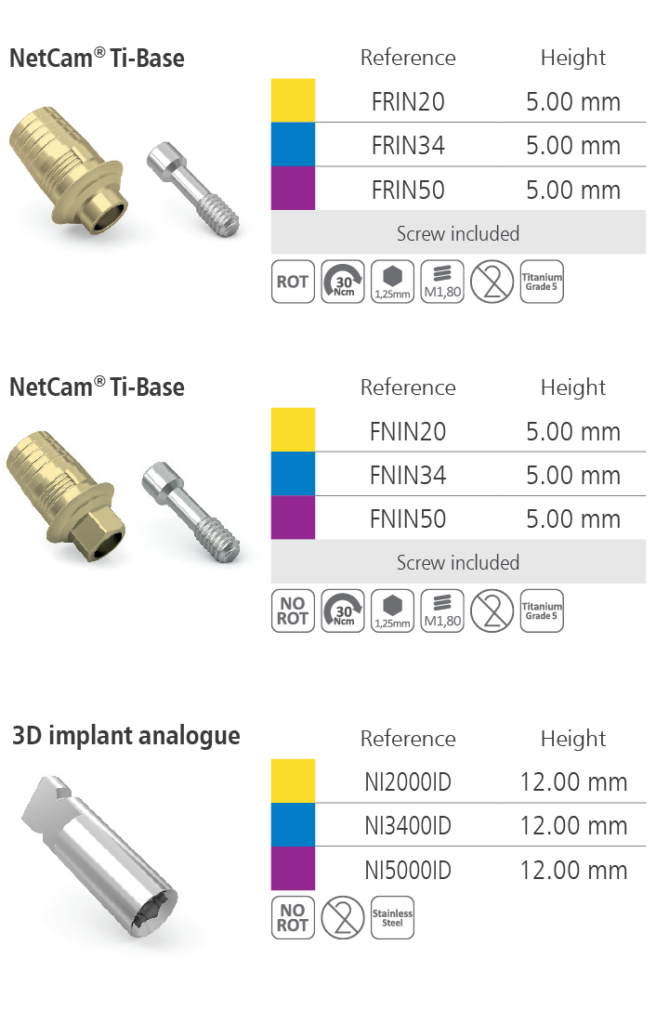

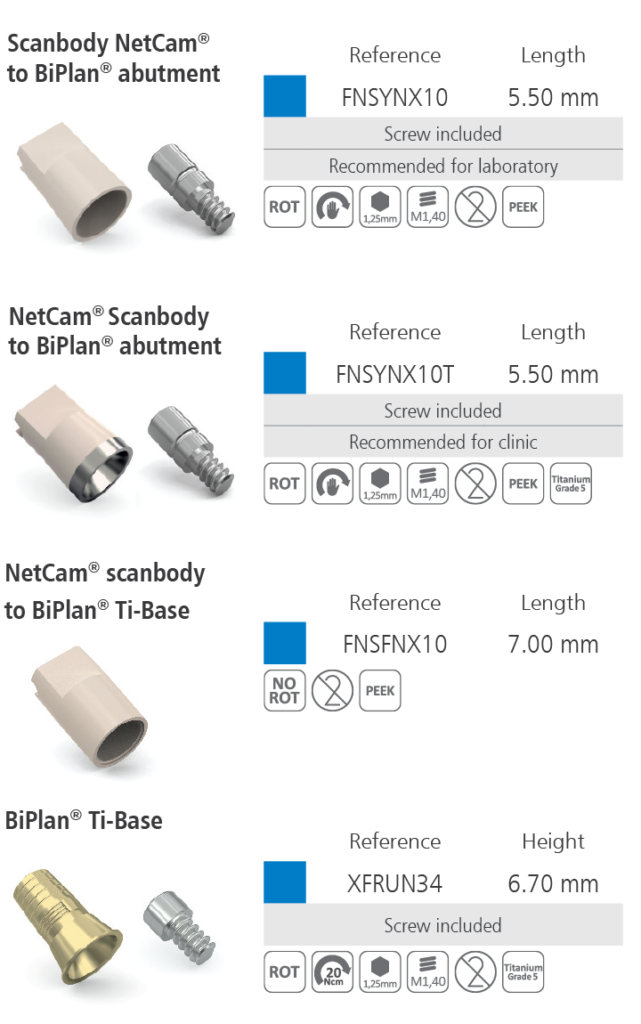

Aditamentos protésicos conexión interna

Screw-retained or cemented prosthesis directly to implant

Titanium provisional - rot.

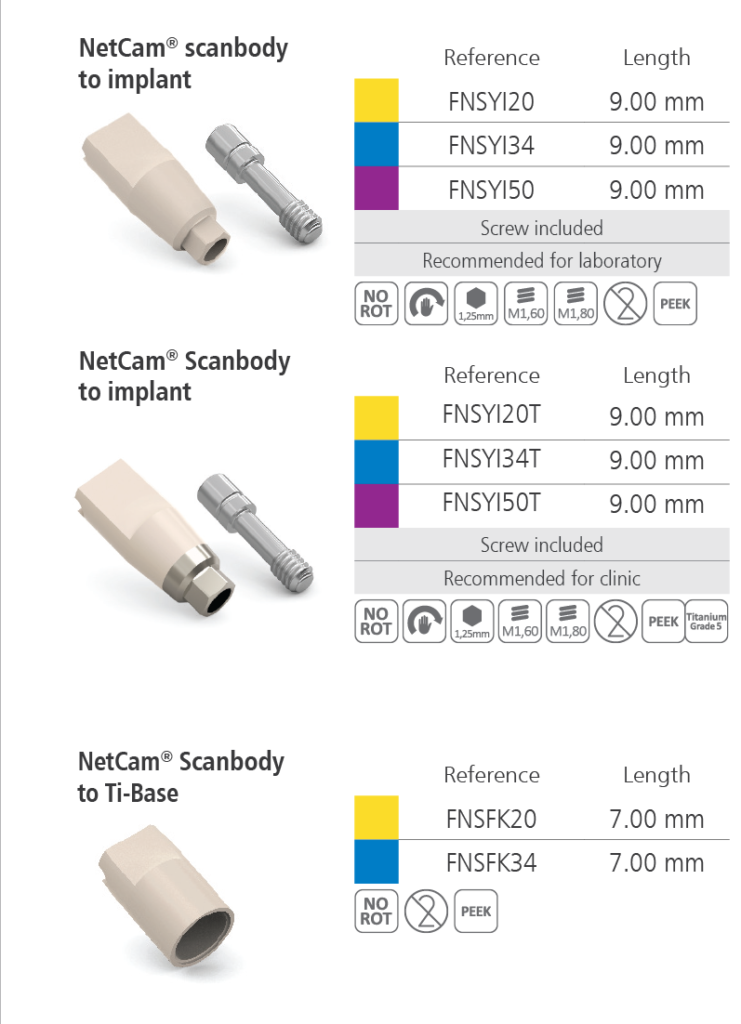

CAD-CAM

Jocker® impression abutment

Jocker® provisional

Jocker® 30° angled abutment

Jocker® analogue

Jocker® clinical screw

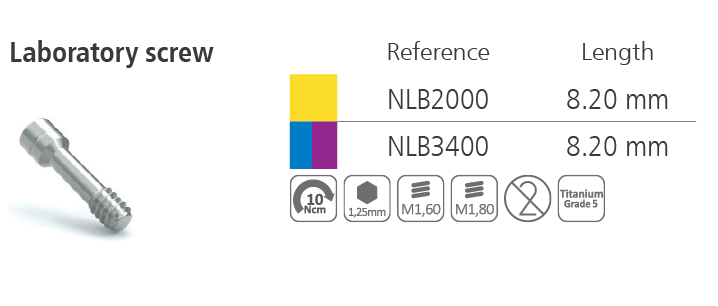

Jocker® laboratory screw